Univers 1600

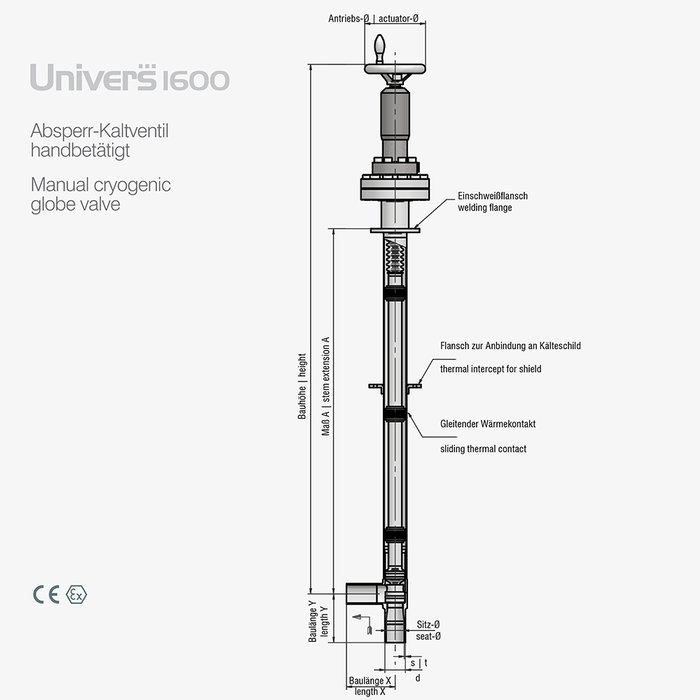

Manual cryogenic globe valve

Univers 1600: valve series for use at cryogenic temperatures down to LHe (1.8 K). Supplied with standard welding flange for vacuum jacketing (optional sizes on request). The valve body optimizes the heat input and shows optimized flow rate (Kv value). Sniffle hole (G 1/8”) to detection chamber/pressure control for supervision of bellow tightness.

Options: Soldered Cu flange as thermal coupling positioned along the extended stem. Sliding thermal contact to cool the valve plug stem from the valve extension outer tube. High-flow surface treatment available (electro-polishing) for decreased blistering.

Series Univers 1600

Abbreviation key

Media temperature

- C = cryogenic temperature

- A = ambient temperature

Pressure range

- LP = low pressure (below 1 bar)

- MP = medium pressure (up to 40/45/63 bar)

- HP = high pressure (250 to 420 bar)

- UHP = ultra-high pressure (420 to 1.000 bar)

Vacuum jacketing

- No = not suitable for installation in vacuum-jacketed pipes

- Std = for installation in vacuum-jacketed pipes

- Opt = suitable for vacuum-jacketed pipes, vacuum flange as option

Function

- GV = Globe valve

- CV = Control valve

- CHK = Check valve

- STR = Strainer

- OV = Overflow valve

- RV = Relief valve

Actuation

- M = manual

- P = electro-pneumatic

- PR = electro-pneumatic with IP regulator

- E = electric

- S = solenoid

- SPR = spring-based

- HY = hydraulic

XXL sizes – a size class of its own.

XXL-fittings up to DN300

Parameters: Univers1600_C_GV_M

| DN | PN | End connection d x s | Height | Length X | Length Y | Extension A | ø Seat | Kvs-Value | Drawing number | Single inquiry |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 40 | 13,0 x 1,5 | A+217 | 38 | 38 | 300…1300 | 2 | 0,15 | 14-1600.2 | Single inquiry |

| 4 | 40 | 13,0 x 1,5 | A+217 | 38 | 38 | 300…1300 | 4 | 0,58 | 14-1600.4 | Single inquiry |

| 6 | 40 | 13,0 x 1,5 | A+217 | 38 | 38 | 300…1300 | 6 | 1,2 | 14-1600.6 | Single inquiry |

| 8 | 40 | 13,0 x 1,5 | A+217 | 40 | 40 | 300…1300 | 2 | 2,0 | 14-1600.8 | Single inquiry |

| 10 | 40 | 17,2 x 1,6 | A+240 | 40 | 40 | 300…1300 | 10 | 3,3 | 14-1600 | Single inquiry |

| 15 | 40 | 21,3 x 2,0 | A+240 | 50 | 50 | 300…1300 | 15 | 7,7 | 14-1601 | Single inquiry |

| 20 | 40 | 26,9 x 2,3 | A+300 | 70 | 70 | 300…1500 | 20 | 14 | 14-1602 | Single inquiry |

| 25 | 40 | 33,7 x 2,0 | A+300 | 80 | 80 | 300…1500 | 25 | 25,3 | 14-1603 | Single inquiry |

| 32 | 40 | 42,4 x 2,0 | A+300 | 80 | 80 | 300…1500 | 32 | 37,1 | 14-1604 | Single inquiry |

| 40 | 40 | 48,3 x 2,0 | A+330 | 100 | 100 | 300…1500 | 40 | 58,9 | 14-1605 | Single inquiry |

| 50 | 40 | 60,3 x 2,0 | A+340 | 100 | 100 | 300…1500 | 50 | 86,7 | 14-1606 | Single inquiry |

| 65 | 40 | 76,1 x 2,0 | A+360 | 125 | 125 | 600…1500 | 65 | 145 | 14-1607 | Single inquiry |

| 80 | 40 | 88,9 x 2,11 | A+380 | 155 | 155 | 600…1500 | 80 | 177 | 14-1608 | Single inquiry |

| 100 | 25 | 114,3 x 2,6 | A+400 | 175 | 175 | 600…1500 | 100 | 276 | 14-1609 | Single inquiry |

| 125 | 10 | 154,0 x 2,0 | A+470 | 200 | 200 | 600…1500 | 125 | 420 | 14-1610 | Single inquiry |

Technical Data

| Technical Data | Technical Design |

|---|---|

| Service fluids | N2, O2, Ar, H2, He, NG* |

| Operating temp. fluid | -271 °C to +50 °C |

| Operating temp. enviroment | -30 °C to +50 °C |

| Body material | stainless steel |

| Actuator | hand wheel |

| Seat sealing | metal/PCTFE seat leakage rate 1*10-6 mbar*l/s |

| Seat sealing | metal/PTFE seat leakage rate 1*10-6 mbar*l/s |

| Seat sealing | metal/metal seat leakage rate 1*10-3 mbar*l/s |

| Body sealing | metal seal ring He leakage rate to atmosphere 1*10-8 mbar*l/s |

| Stem sealing | stainless steel bellow physically tight |

| 2nd stem sealing | safety-O-ring/grooved ring (Viton) |

| Position indication | scale |

| Surface treatment | machined, ground, electro-polished or passivated** |

| Body shape | angle |

| Installation position | horizontal in flow direction, actuator on top, max. 30° vertical |

| Material certificates | DIN EN 10204/3.1 AD2000-A4 |

| Welding flange | standard for vacuum insulated tubes |

* All dangerous, toxic or acid fluids according to material compatibility.

**Surface treatment can be choosen according to customer specification. See product options