The following product options offer a variety of options for configuring the valves from STÖHR ARMATUREN in addition to the standard shown according to customer request. These include the actuators to be used or electrical attachments from different manufacturers according to customer's plant standards.

Further information or current data sheets for download can be found on the website of the respective manufacturer for purchased parts.

If a desired version or product option is not listed on this homepage or in the STÖHR product catalog, please inquire directly with our technical sales department.

Actuators

Diaphragm

Diaphragm actuators

Actuators for: pneumatic globe valves and control valves

| OEM | Embedded into | Brief description |

|---|---|---|

| RTK | Series 900, 1200, 1600, Specials | ST 6115 - 120 cm², ST 6135 - 280 cm², ST 6160 - 530 cm², ST 6175 - 1000 cm² |

| Samson | Series 900, 1200, 1600, Specials | 3277 120 cm²… 2 x 2800 cm² |

| Sart von Rohr | Series 900, 1200, 1600, Specials | PA 15 (95 cm²) bis PA 60 (400cm²), MA 15 (800 cm²) und MA 60 (1730 cm²) |

Pneumatic

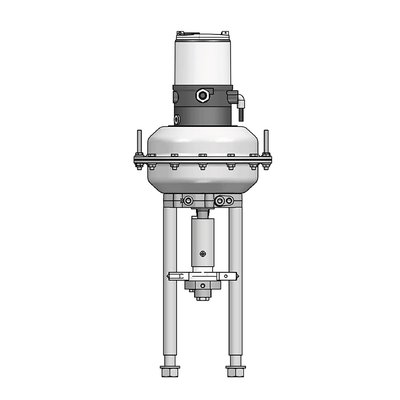

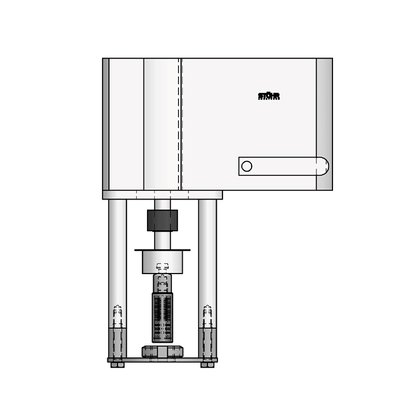

STÖHR pneumatic actuator

for globe valves

Operating pressure: 6 bar +0.5 /-0.0 bar (standard), Expandable up to max. 50 bar (on request)

Outer diameter: 120, 155, 220, 285, 400mm (close up)

Standard mounting parts: inductive limit switches (EX), 3/2-way solenoid pilot valve (EX)

Optional mounting parts: plug and mating connector (non-EX) for limit switches, pressure reducer for operating pressure

Attention: Depending on the volume of the pneumatic actuator and the resulting weight, opening and closing speed, valve size, etc., a separate mounting of the actuator is recommended. It is to be provided by the plant engineer or the operator on site!

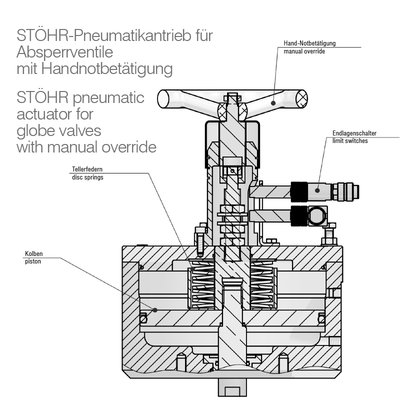

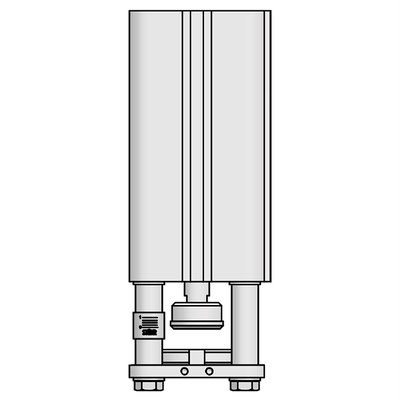

STÖHR pneumatic actuator with manual override

for globe valves

Operating pressure: 6 bar +0.5 /-0.0 bar (standard), Expandable up to max. 50 bar (on request)

Outer diameter: 120, 155, 220, 285, 400mm (close up)

Standard mounting parts: inductive limit switches (EX), 3/2-way solenoid pilot valve (EX)

Optional mounting parts: plug and mating connector (non-EX) for limit switches, pressure reducer for operating pressure, maritine execution, manual override

Attention: Depending on the volume of the pneumatic actuator and the resulting weight, opening and closing speed, valve size, etc., a separate mounting of the actuator is recommended. It is to be provided by the plant engineer or the operator on site!

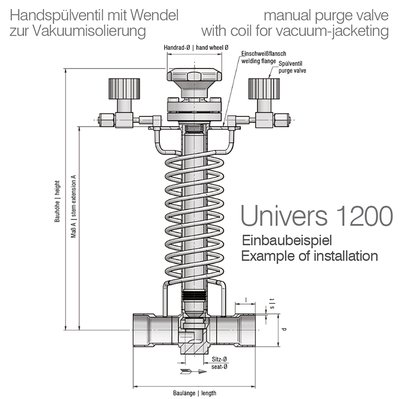

Univers 1200 Ambient

Univers 1200 ambient pneumatic aktuators

| DN [mm] | PN [barÜ] | Fail-safe position | Piston ø [mm] | Operating Pressure [barÜ] | Lifting height [mm] | Dead volume [l] | Cubic capacity [l] | Drawing no. |

|---|---|---|---|---|---|---|---|---|

| 10 | 40 | NC | 84 | 6,0 + 0,5 | 4 ± 1 | 0,08 | 0,02 | 18-1200 |

| 10 | 40 | NO | 84 | 6,0 + 0,5 | 4 ± 1 | 0,04 | 0,02 | 18-1200 |

| 15 | 40 | NC | 84 | 6,0 + 0,5 | 4 ± 1 | 0,08 | 0,02 | 18-1201 |

| 15 | 40 | NO | 84 | 6,0 + 0,5 | 4 ± 1 | 0,04 | 0,02 | 18-1201 |

| 20 | 40 | NC | 125 | 6,0 + 0,5 | 5 ± 1 | 0,3 | 0,06 | 18-1202 |

| 20 | 40 | NO | 125 | 6,0 + 0,5 | 5 ± 1 | 0,28 | 0,06 | 18-1202 |

| 25 | 40 | NC | 125 | 6,0 + 0,5 | 5 ± 1 | 0,3 | 0,06 | 18-1203 |

| 25 | 40 | NO | 125 | 6,0 + 0,5 | 5 ± 1 | 0,28 | 0,06 | 18-1203 |

| 32 | 40 | NC | 185 | 6,0 + 0,5 | 10 ± 1 | 0,57 | 0,27 | 18-1204 |

| 32 | 40 | NO | 185 | 6,0 + 0,5 | 10 ± 1 | 0,88 | 0,26 | 18-1204 |

| 40 | 40 | NC | 185 | 6,0 + 0,5 | 10 ± 1 | 0,57 | 0,27 | 18-1205 |

| 40 | 40 | NO | 185 | 6,0 + 0,5 | 10 ± 1 | 0,88 | 0,26 | 18-1205 |

| 50 | 40 | NC | 185 | 6,0 + 0,5 | 12 ± 1 | 0,54 | 0,32 | 18-1206 |

| 50 | 40 | NO | 185 | 6,0 + 0,5 | 12 ± 1 | 1,61 | 0,31 | 18-1206 |

| 65 | 25 | NC | 242 | 6,0 + 0,5 | 20 ± 1,5 | 0,88 | 0,91 | 18-1207 |

| 65 | 25 | NO | 242 | 6,0 + 0,5 | 20 ± 1,5 | 5,74 | 0,89 | 18-1207 |

| 80 | 25 | NC | 242 | 6,0 + 0,5 | 20 ± 1,5 | 0,88 | 0,91 | 18-1208 |

| 80 | 25 | NO | 242 | 6,0 + 0,5 | 20 ± 1,5 | 5,74 | 0,89 | 18-1208 |

| 100 | 25 | NC | 345 | 6,0 + 0,5 | 25 ± 2 | 1,79 | 2,33 | 18-1209 |

| 100 | 25 | NO | 345 | 6,0 + 0,5 | 25 ± 2 | 2,55 | 2,27 | 18-1209 |

Univers 1200 Cryogenic

Univers 1200 cryogenic pneumatic aktuators

| DN [mm] | PN [barÜ] | Fail-safe position | Piston ø [mm] | Operating Pressure [barÜ] | Lifting height [mm] | Dead volume [l] | Cubic capacity [l] | Drawing no. |

|---|---|---|---|---|---|---|---|---|

| 10 | 40 | NC | 84 | 6,0 + 0,5 | 4 ± 1 | 0,08 | 0,02 | 18-1200 |

| 10 | 40 | NO | 84 | 6,0 + 0,5 | 4 ± 1 | 0,04 | 0,02 | 18-1200 |

| 15 | 40 | NC | 84 | 6,0 + 0,5 | 4 ± 1 | 0,08 | 0,02 | 18-1201 |

| 15 | 40 | NO | 84 | 6,0 + 0,5 | 4 ± 1 | 0,04 | 0,02 | 18-1201 |

| 20 | 40 | NC | 125 | 6,0 + 0,5 | 5 ± 1 | 0,3 | 0,06 | 18-1202 |

| 20 | 40 | NO | 125 | 6,0 + 0,5 | 5 ± 1 | 0,28 | 0,06 | 18-1202 |

| 25 | 40 | NC | 125 | 6,0 + 0,5 | 5 ± 1 | 0,3 | 0,06 | 18-1203 |

| 25 | 40 | NO | 125 | 6,0 + 0,5 | 5 ± 1 | 0,28 | 0,06 | 18-1203 |

| 32 | 40 | NC | 185 | 6,0 + 0,5 | 10 ± 1 | 0,57 | 0,27 | 18-1204 |

| 32 | 40 | NO | 185 | 6,0 + 0,5 | 10 ± 1 | 0,88 | 0,26 | 18-1204 |

| 40 | 40 | NC | 185 | 6,0 + 0,5 | 10 ± 1 | 0,57 | 0,27 | 18-1205 |

| 40 | 40 | NO | 185 | 6,0 + 0,5 | 10 ± 1 | 0,88 | 0,26 | 18-1205 |

| 50 | 40 | NC | 185 | 6,0 + 0,5 | 12 ± 1 | 0,54 | 0,32 | 18-1206 |

| 50 | 40 | NO | 185 | 6,0 + 0,5 | 12 ± 1 | 1,61 | 0,31 | 18-1206 |

| 65 | 40 | NC | 242 | 6,0 + 0,5 | 20 ± 1,5 | 0,88 | 0,91 | 18-1207 |

| 65 | 40 | NO | 242 | 6,0 + 0,5 | 20 ± 1,5 | 5,74 | 0,89 | 18-1207 |

| 80 | 25 | NC | 242 | 6,0 + 0,5 | 20 ± 1,5 | 0,88 | 0,91 | 18-1208 |

| 80 | 25 | NO | 242 | 6,0 + 0,5 | 20 ± 1,5 | 5,74 | 0,89 | 18-1208 |

| 100 | 25 | NC | 345 | 6,0 + 0,5 | 25 ± 2 | 1,79 | 2,33 | 18-1209 |

| 100 | 25 | NO | 345 | 6,0 + 0,5 | 25 ± 2 | 2,55 | 2,27 | 18-1209 |

Univers 4200 Ambient

Univers 4200 ambient pneumatic aktuators

| DN [mm] | PN [barÜ] | Fail-safe position | Piston ø [mm] | Operating Pressure [barÜ] | Lifting height [mm] | Dead volume [l] | Cubic capacity [l] | Drawing no. |

|---|---|---|---|---|---|---|---|---|

| 4 | 250 | NC | 185 | 6,0 + 0,5 | 3± 0,5 | 0,75 | 0,08 | 18-4200 |

| 4 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4200 |

| 6 | 250 | NC | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,75 | 0,08 | 18-4201 |

| 6 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4201 |

| 8 | 250 | NC | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,75 | 0,08 | 18-4202 |

| 8 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4202 |

| 10 | 250 | NC | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,75 | 0,08 | 18-4203 |

| 10 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4203 |

| 15 | 250 | NC | 242 | 6,0 + 0,5 | 5 ± 1 | 0,89 | 0,23 | 18-4204 |

| 15 | 250 | NO | 242 | 6,0 + 0,5 | 5 ± 1 | 2,56 | 0,22 | 18-4204 |

| 20 | 250 | NC | 242 | 6,0 + 0,5 | 5 ± 1 | 0,89 | 0,23 | 18-4205 |

| 20 | 250 | NO | 242 | 6,0 + 0,5 | 5 ± 1 | 2,56 | 0,22 | 18-4205 |

| 25 | 250 | NC | 345 | 6,0 + 0,5 | 7 ± 1 | 6,52 | 6,65 | 18-4206 |

| 25 | 250 | NO | 345 | 6,0 + 0,5 | 7 ± 1 | 6,76 | 6,63 | 18-4206 |

Univers 4200 Cryogenic

Univers 4200 cryogenic pneumatic aktuators

| DN [mm] | PN [barÜ] | Fail-safe position | Piston ø [mm] | Operating Pressure [barÜ] | Lifting height [mm] | Dead volume [l] | Cubic capacity [l] | Drawing no. |

|---|---|---|---|---|---|---|---|---|

| 4 | 250 | NC | 185 | 6,0 + 0,5 | 3± 0,5 | 0,75 | 0,08 | 18-4200 |

| 4 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4200 |

| 6 | 250 | NC | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,75 | 0,08 | 18-4201 |

| 6 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4201 |

| 8 | 250 | NC | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,75 | 0,08 | 18-4202 |

| 8 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4202 |

| 10 | 250 | NC | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,75 | 0,08 | 18-4203 |

| 10 | 250 | NO | 185 | 6,0 + 0,5 | 3 ± 0,5 | 0,87 | 0,08 | 18-4203 |

| 15 | 250 | NC | 242 | 6,0 + 0,5 | 5 ± 1 | 0,89 | 0,23 | 18-4204 |

| 15 | 250 | NO | 242 | 6,0 + 0,5 | 5 ± 1 | 2,56 | 0,22 | 18-4204 |

| 20 | 250 | NC | 242 | 6,0 + 0,5 | 5 ± 1 | 0,89 | 0,23 | 18-4205 |

| 20 | 250 | NO | 242 | 6,0 + 0,5 | 5 ± 1 | 2,56 | 0,22 | 18-4205 |

| 25 | 250 | NC | 250 | 6,0 + 0,5 | 8 ± 1 | 7,46 | 6,38 | 18-4206 |

| 25 | 250 | NO | 250 | 6,0 + 0,5 | 8 ± 1 | 8,92 | 6,38 | 18-4206 |

Electric

Electric actuator

Actuator for: globe valves and control valves

| OEM | Actuator-type | Designation | Embedded into | Brief description |

|---|---|---|---|---|

| Sauter | Electric actuator | AVF234S | Serie 900, 1200, Specials | Electric fail safe actuator for On/Off- and regulating valves |

| Schischek | Electric actuator | ExMax | Serie 900, 1200, Specials | Electric fail safe actuator for On/Off- and regulating valves |

| RTK | Electric actuator | ST 5112, ST 5113, ST 5114, ST 5106, ST 5116 | Serie 1200, Specials | Electric actuator for On/Off- and regulating valves |

| Auma | Electric actuator | SVC 07.1 | Serie 1200, 4200, 4300, 7100, Specials | Part-turn actuator |

| Kendrion | 24 V DC solenoid | 41130226 | Serie 900, Specials | for On/Off- valves |

| Magnet-Schultz | 24 V DC solenoid | GTLX 120 W43 D06 | Serie 1200, Specials | for On/Off- valves |

Piston

Piston actuator

Actuators for: pneumatic globe valves and control valves

| OEM | Embedded into | Brief description |

|---|---|---|

| Stöhr | Series 800, 1200, 3200, 4200, 4300, 7100, Specials | Piston diameter 84…400 mm, control pressure 6 + 0,5 barG, NO or NC |

| Joyner | Series 900, Specials | Piston diameter 40…125 mm, control pressure 6 + 0,5 barG, NO or NC |

| FESTO | Series 900, Specials | Piston diameter 40…125 mm, control pressure 6 + 0,5 barG, NO or NC |

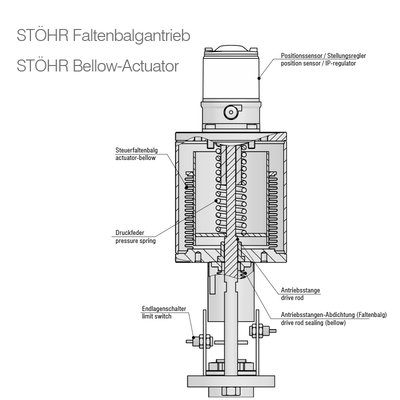

Bellow

STÖHR bellow-actuator

Special feature: radiation-proof, limit switches, filter regulator, manual override

Operating pressure: 6 bar +0.5 /-0.0 bar (standard), expandable up to max. 50 bar (on request)

Outer diameter: 120, 155, 220, 285, 400mm

Standard mounting parts: inductive limit switches (EX), 3/2-way solenoid pilot valve (EX)

Optional: radiation-proof limit switches, filter regulator, manual override

Attention: Depending on the volume of the bellow actuator and the resulting weight, opening and closing speed, valve size, etc., a separate mounting of the actuator is recommended. It is to be provided by the plant engineer or the operator on site!

Mounting parts

Limit switch

Limit switch

Mounting parts for: manual, pneumatic globe and control valves

| OEM | Type | Embedded into | Brief description |

|---|---|---|---|

| Pepperl + Fuchs | NJ2-11-N-G ex | Series 800, 900, 1200,1600, 3200, 4200, Specials | 2-wire Namur NC ATEX II2G |

| Pepperl + Fuchs | NJ2-12GM40-E | Series 800, 900, 1200,1600, 3200, 4200, Specials | 3-wire NPN NO |

| Pepperl + Fuchs | NJ2-12GM40-E2 | Series 800, 900, 1200,1600, 3200, 4200, Specials | 3-wire PNP NO |

| Westlock | Silver Bullet 316 SB | Serie 800, 900, 1200,1600, 3200, 4200, Specials | Reed |

| Turck | BIM-UNT-AY1X/S1139 ex | Series 900 | 2-wire Namur NO ATEX II1G |

Solenoid valve

3/2-way solenoid valve

Mounting parts in serial execution for: pneumatic globe valves and control valves

| OEM | Type | Embedded into | Brief description |

|---|---|---|---|

| Bürkert | 6014 | Series 800, 900, 1200,1600, 3200, 4200, Specials | G1/8", 24V DC, with coupler socket 2508 |

| Bürkert | 643-C | Series 800, 900, 1200,1600, 3200, 4200, Specials | G1/8", 24V DC, ATEX |

| Joyner | MH 311013 | Series 800, 900, 1200,1600, 3200, 4200, Specials | G1/8", 24V DC, with coupler socket |

| Joyner | MH 311013 | Series 800, 900, 1200,1600, 3200, 4200, Specials | G1/8", 24V AC, with coupler socket |

| Joyner | MH 311013 | Series 800, 900, 1200,1600, 3200, 4200, Specials | G1/8", 230V AC, with coupler socket |

| Joyner | MH 311015 | Series 800, 900, 1200,1600, 3200, 4200, Specials | G1/8", 24V DC, ATEX, TT, with coupler socket |

Control valve

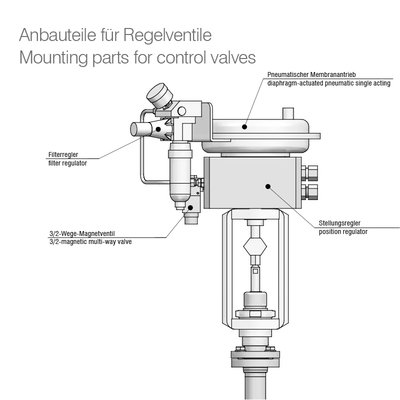

Mounting parts

for control valves

Position regulator for control valves

- direct mounting below or on top of the pneumatic actuator

- linear or equal percentage characteristic

- signal range 4 to 20 mA

Filter regulator for compressed-air supply of pneumatic actuators consisting of:

- pressure reducing valve

- airfilter

- pressure gauge

Position regulator

Position regulator

Mounting parts for: Standard control valves

| OEM | Type | Embedded into | Brief description | Options |

|---|---|---|---|---|

| Samson | 3730-0 | Series 900, 1200,1600, Specials | 2-wire, 4 – 20 mA, DIP-switches, SSP-interface | ATEX, stainless steel housing |

| Samson | 3730-1 | Series 900, 1200,1600, Specials | 2-wire, 4 – 20 mA, LCD and Autotune, 2 software limit contacts, SSP-interface | ATEX, induktive limit contact, stainless steel housing |

| Samson | 3730-2 | Series 900, 1200,1600, Specials | 2-wire, 4 – 20 mA, LCD and Autotune, Diagnose EXPERTplus, 1 fault alarm contact, 2 software limit contacts, SSP-interface | ATEX, induktive limit contact, stainless steel housing, solenoid valve, analog position transmitter, external position sensor, leakage sensor, binary input |

| Samson | 3730-3 | Series 900, 1200,1600, Specials | 2-wire, 4 – 20 mA, LCD and Autotune, Hart-communication, diagnose EXPERTplus, 2 software limit contacts, 1 fault alarm contact, SSP-interface | ATEX, induktive limit contact, stainless steel housing, solenoid valve, analog position transmitter, external position sensor, leakage sensor, binary input |

| Siemens | Sipart PS2 | Series 900, 1200,1600, Specials | Automatic initialization, LCD-Display | ATEX, analog position transmitter, alarm module, Profibus PA, Hart protocol, Foundation Fieldbus, pressure resistant aluminium housing, stainless steel housing, external position sensor |

| Bürkert | 3694 | Series 900, Specials | 4 – 20 mA, Digitaleingang, DIP-Schalter, ATEX II3G, contact-free travel measurement, communication interface | analog position transmitter, AS-Interface (Fieldbus system) |

| Bürkert | 3692/3693 | Series 900, Specials | 4 – 20 mA, 0-10 V, digital input, graphic display, ATEX II3G, contact-free travel measurement, communication interface | analog position transmitter, 2 binary outputs, Profibus |

Vacuum insulation

Welding flange

welding flange

| DN (mm) | Sticks 900 | Univers 1200 | Univers 1600 Vers. 1 | Univers 1600 Vers. 2 |

|---|---|---|---|---|

| 4, 6 , 8 | – | – | – | – |

| 10 | – | 109 | 60 | 84 |

| 15 | 72,1 | 109 | 60 | 84 |

| 20 | – | 109 | 80 | 134 |

| 25 | 72,1 | 109 | 80 | 134 |

| 32 | – | 135 | 80 | 134 |

| 40 | – | 135 | 120 | 164 |

| 50 | 163 | 149 | 120 | 164 |

| 65 | – | 212 | 150 | 200 |

| 80 | – | 212 | 190 | 260 |

| 100 | – | 266 | 230 | 315 |

| 125 | – | – | 275 | 315 |

Vacuum jacketing

Vacuum jacketing

STICKS series 900 and other cryogenic valve series are available with factory-provided multi-layer absorption insulation material (MLI) and jacketing for quick installation within vacuum-insulated piping systems. All cryogenic valves can be ordered with optional factory-fitted, pre-installed housing.

The valve body is wrapped with a multi-layer absorption insulation material for high thermal quality. The stainless steel housing is welded to the standard pre-installed welding flange. The jacketed valves can be pre-configured with couplings or an open pipe for connection.

General construction and delivery features

- Welded housing made from corrosion-resistant stainless steel

- Housing can optionally be supplied with an polished surface treatment

- Delivery includes leak test at the outer side of the housing

- Preparation for connections with quick-release plug-in couplings according to customer requirement (optional)

- Proven multi-layer absorption material for the super insulation to achieve a high thermal quality

- Connections for vacuum pump and vacuum gauge available as additional housing features for quick-release coupling system (optional)

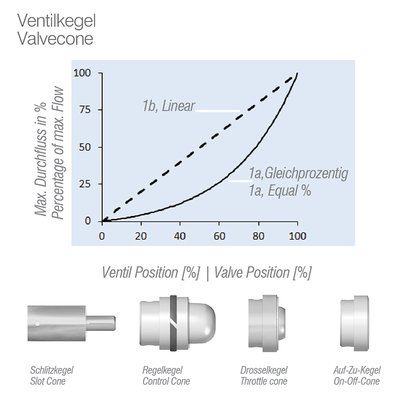

Valve cone

Valve cone

| Valve function | Cone type | Valve plugs | Execution |

|---|---|---|---|

| Globe valves | Valve cones for globe valves both at ambient ad cryogenic temperature are identical | ||

| On-off cone type | Flat shaped cone with digital characteristic for optimal tightness at seat | standard | |

| Control valves | Valve cones for control valves both at ambient and cryogenic temperature are identical | ||

| To modify Kv-value or flow characteristics, valve cone can be exchanged. | |||

| Cone with equal percentage characteristic | Flow characteristic equal | standard | |

| Cone with linear control characteristic | Flow characteristic linear | optional | |

| Throttle cone | Combination of flat shaped cone for sealing with control characteristic for slowly increasing media flow during opening | optional | |

| Slot cone | Control cone for lowest medium passage (JT effect) | optional | |

| Customer specific control characteristic | Cone design for special flow characteristic acc. to customer specification | optional |

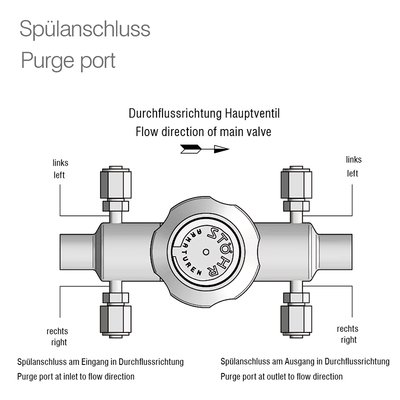

Purge

Purge port

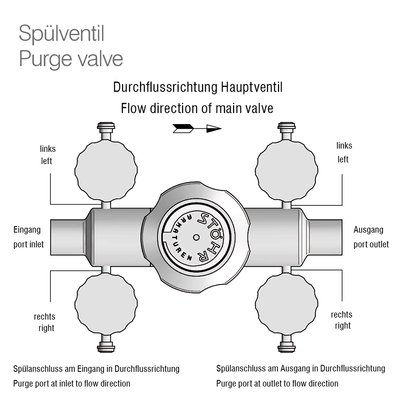

Purge valve

Purge Valve

Diaphragm valve 316 L ½”

- operating temperature -40 °C to+65 °C

- inlet ½” butt-welded connection

- outlet ½” VCR male with seal disc and blind cap

- purge valve welded to main valve right/left to flow direction

- purge direction to the outside

Executions:

- VCR* or other suppliers

- male/female execution

- with/without blind plug/blind cover

The length of the main valve may differ from standard sizes.

Manual purge

Materials and surfaces

Sealing

Sealing options

STÖHR ARMATUREN uses PCTFE as standard sealing material for both ambient and cryogenic temperature valves. Depending on medium type, medium temperature and pressure rate, other materials may be recommended.

Resilient seal: PTFE, FPM, FKM, EPDM, PU, Torlon®, Vespel©

Metallic seal: copper, nickel, stainless steel or stellit

Housing

Standard material qualities

| Material | AISI |

|---|---|

| 1.4301 | 304 |

| 1.4306 | 304L |

| 1.4401 | 316 |

| 1.4404 | 316L |

| 1.4406 | 316LN |

| 1.4435 | 316L |

| 1.4436 | 316L |

| 1.4541 | 321 |

| 1.4550 | 347 |

| 1.4571 | 316Ti |

| 1.4580 | 316Cb |

![[Translate to Englisch:] pneumatikantrieb für Absperrventile](/fileadmin/_processed_/8/f/csm_pneumatic-antrieb_50a19e205e.jpg)

![[Translate to Englisch:] Endlagenschalter](/fileadmin/_processed_/c/e/csm_endlagenschalter_c7ec5d90d4.jpg)