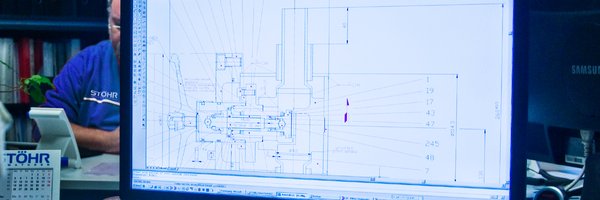

Production-integrated quality checks and final acceptance test (FAT) are carried out based on a defined quality plan:

- Vision test with control of weld DIN EN ISO 5817

- Functional test DIN EN 12266-2

- Hydraulic pressure test DIN EN 12266-1

- Helium leak test for control of tightness to outside DIN 1779

- Final quality inspection before packing

QA and acceptance tests that can be provided on request:

- Non-destructive material test (NDT)

- Cold test in liquid nitrogen (LIN)

- Surface crack test by dye penetrant DIN EN ISO 3452

- X-Ray examination DIN EN ISO 17636

- Ultrasonic test DIN EN ISO 22825

- Clean room assembly and test (up to class 100)

Further test methods and testing services can be performed in cooperation with qualified partner companies, according to your specifications.

Final acceptance tests may be performed in the presence of customer representatives or external inspectors.

Best for Helium - and nothing gets lost.

We offer solutions for liquid helium applications.Valves from STÖHR optimize effort and cost for an efficient transport of the medium to and within your gas plant.

Best for Helium

When used in 24 / 7 / 52 continuous operation, STÖHR valves are not immune to errors, despite their tried and tested design, the use of the best materials and careful processing during assembly and testing. If this happens, we offer support:

Valve Service

Exhibitions, Congresses, Events: Your chance to meet, greet and share opinions with the team of STÖHR ARMATUREN.

Exhibitions, Congresses

Discover the team behind the technology, and read about our history and progress with the development and manufacture of high-quality products for the global market since 1938.