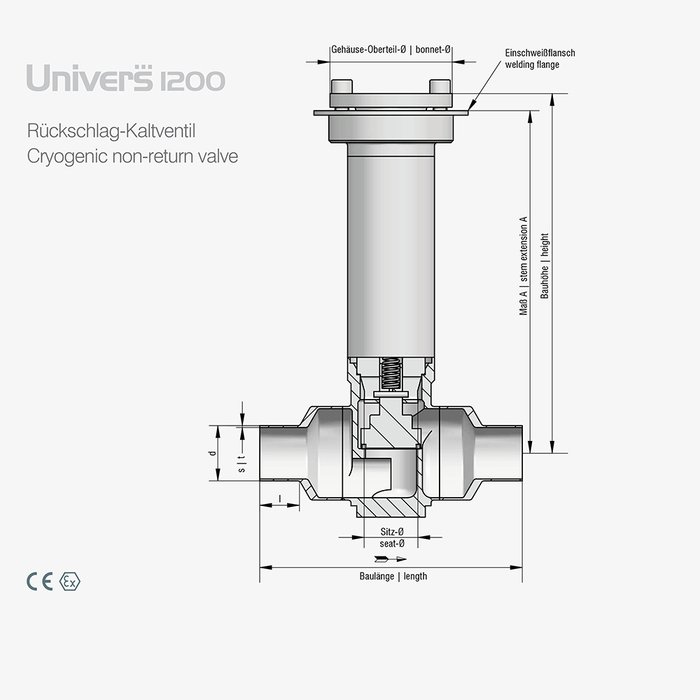

Univers 1200

Cryogenic non-return valve

Univers 1200: reliable and high quality stainless steel non-return valve for cryogenic, gaseous and liquid media. Safely responding with low minimum opening pressure. The valve body is machined from one piece of solid stainless steel. End connections can be supplied in butt-welded execution or according to customer specification.

Series Univers 1200

Abbreviations keys

Abbreviation key

Media temperature

- C = cryogenic temperature

- A = ambient temperature

Pressure range

- LP = low pressure (below 1 bar)

- MP = medium pressure (up to 40/45/63 bar)

- HP = high pressure (250 to 420 bar)

- UHP = ultra-high pressure (420 to 1.000 bar)

Vacuum jacketing

- No = not suitable for installation in vacuum-jacketed pipes

- Std = for installation in vacuum-jacketed pipes

- Opt = suitable for vacuum-jacketed pipes, vacuum flange as option

Function

- GV = Globe valve

- CV = Control valve

- CHK = Check valve

- STR = Strainer

- OV = Overflow valve

- RV = Relief valve

Actuation

- M = manual

- P = electro-pneumatic

- PR = electro-pneumatic with IP regulator

- E = electric

- S = solenoid

- SPR = spring-based

- HY = hydraulic

XXL sizes – a size class of its own.

XXL-fittings up to DN300

Parameters: Univers1200_C_CHK_SPR

| DN | PN | End connection d x s x l | Length | Height | Extension A | ø Seat | Drawing number | Single inquiry |

|---|---|---|---|---|---|---|---|---|

| 10 | 40 | 17,2 x 1,6 x 25 | 160 | 350 | 300 | 15 | 08-1200.12.3 | Single inquiry |

| 15 | 40 | 21,3 x 1,6 x 25 | 160 | 350 | 300 | 15 | 08-1201.12.12 | Single inquiry |

| 20 | 40 | 26,9 x 1,6 x 25 | 180 | 350 | 300 | 25 | 08-1202.12.8 | Single inquiry |

| 25 | 40 | 33,7 x 2,0 x 25 | 180 | 350 | 300 | 25 | 08-1202.12.19 | Single inquiry |

| 32 | 40 | 42,4 x 2,0 x 30 | 250 | 330 | 300 | 36 | 08-1204.12.3 | Single inquiry |

| 40 | 40 | 48,3 x 2,0 x 35 | 250 | 330 | 300 | 36 | 08-1205.12.1 | Single inquiry |

| 50 | 40 | 60,3 x 2,0 x 50 | 250 | 330 | 300 | 45 | 08-1206.12.2 | Single inquiry |

| 65 | 40 | 76,1 x 2,3 x 50 | 270 | 570 | 500 | 60 | 08-1207.12.1 | Single inquiry |

| 80 | 40 | 88,9 x 2,3 x 50 | 300 | 570 | 500 | 75 | 08-1208.12.3 | Single inquiry |

| 100 | 40 | 114,3 x 2,6 x 50 | 350 | 900 | 800 | 100 | 08-1209.12.1 | Single inquiry |

Technical Data

| Technical Data | Technical Design |

|---|---|

| Service fluids | N2, O2, Ar, H2, He, NG* |

| Operating temp. fluid | -196 °C (-269 °C) to +50 °C |

| Operating temp. enviroment | -30 °C to +50 °C |

| Body material | stainless steel |

| Body sealing | metal seal ring |

| Surface treatment | machined, ground, electro-polished or passivated** |

| Minimum opening pressure | ≤ 0,3 bar |

| Body shape | straight through |

| Installation position | horizontal flow, bonnett on top |

| Material certificates | DIN EN 10204/3.1 AD2000-A4 |

| Welding flange | opional for vacuum insulated tubes |

* All dangerous, toxic or acid fluids according to material compatibility.

**Surface treatment can be choosen according to customer specification. See product options